Horizontal Spiral Belt Mixer

- Details

- Feedback

Descriptions

The horizontal spiral belt mixer consists of a container, a screw stirring blade and a transmission unit. The helical mixing device is usually made into two or three layers in which the external blade pushes the material into the corner and the internal part is used to transport the material to both sides to create convection through mixing. Containers can be rounded to facilitate reaction and drying in subsequent steps.

Principle

The mixer adopts u-type barrel structure, smooth operation, uniform stirring, no dead angle, clean discharge and wide application range. The mixer mainly has wear-resistant alloy material manufacture, including high speed agitating blade, stirring wing, wear-resisting lining, stirring arm, stirring shovel, planet shovel, stirring plough knife, stirring rod, stirring rake and so on. Mixer is a machine which uses mechanical force and gravity to mix two or more materials evenly.

Features

● High loading coefficient and small occupied area.

● Hard to clean when mixing materials with viscosity or coherence.

Application

The spiral belt mixer is suitable for mixing viscous materials or coherent particles as well as particles with liquid or paste. It also applies to mixing a large amount of infrequently changed materials, which are difficult to clean after mixing them.

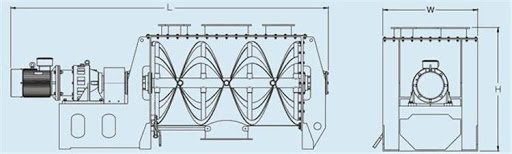

Schematic Structure

Technical Parameters

Technical data:

| Model | Capacity ( L ) | Power ( Kw) | Speed (Rpm) | Weight (Kg) |

| MRB-50 | 50 | 3 | 60 | 400 |

| MRB-100 | 100 | 4 | 60 | 600 |

| MRB-200 | 200 | 7.5 | 41 | 800 |

| MRB-300 | 300 | 7.5 | 41 | 1500 |

| MRB-500 | 500 | 11 | 33 | 1800 |

| MRB-1000 | 1000 | 18.5 | 26 | 2000 |

| MRB-1500 | 1500 | 22 | 26 | 2500 |

| MRB-2000 | 2000 | 30 | 20 | 3200 |

| MRB-3000 | 3000 | 37 | 20 | 6000 |

| MRB-5000 | 5000 | 55 | 20 | 9500 |

| MRB-12000 | 12000 | 110 | 18 | 15000 |

Note: the equipment above could be divided into two types based on their materials—carbon steel (C) and stainless steel.

Q & A

Q 1: Why is the motor unable to overheat?

A: Possible reasons are

1) Motor is in two-phase operation;

2) Motor has internal short circuit;

3) Long-term overload operation;

4) voltage too low.

Solutions:

1) Stop the machine and check all connections of electrical equipment;

2) reduce loading;

3) tighten the loose parts;

4) operate after voltage is stable.

Q 2: What’s the cause of the abnormal noise in the mixer?

A: Possible reasons are

1) foreign objects in the machine;

2) chain is loose;

3) some parts of rotor is broken.

Solutions:

1) remove foreign objectives;

2) adjust the chain or change the chain;

3) fix the rotor.

Q 3: What is the cause of overheating of bearings?

A: Possible reasons are

1) too much or too less lubricant oil;

2) bearing damage;

3) too tight belt;

4) oil seal damage due to long-term over-loading running.

Solutions:

1) reduce loading and tighten the belt;

2) remove foreign objects;

3) change bearing;

4) change seal ring.

Q 4: What is the cause of reducer gets heat?

A: Reason is lacking oil or damage of internal parts.

Solution is to add oil to required level, repair or change the reducer.

Q 5: What is the cause of no output of reducer?

A: Possible reasons are motor running normally but reducer malfunction, or the pin arrow at the joint is badly worn.

Solution is to change a new pin arrow.

Q 6: How should we troubleshoot the screw belt mixer when it breaks down?

A: 1) In the course of use, if a sudden shutdown is found, the motor should be started after the discharging door is opened.

2) If there is a powder leak in the discharge door, we should check the contact between the discharge door and the housing of the seal, such as fastening the door sealing or seal aging, should adjust the position of the stroke switch or replace the seal.

3) If the discharge mechanism does not work properly, we should check cylinder and gas supply system for failure.

←Previous: Compound Fertilizer Granulator

Next: Powder Double Cone Mixer→