Our Services

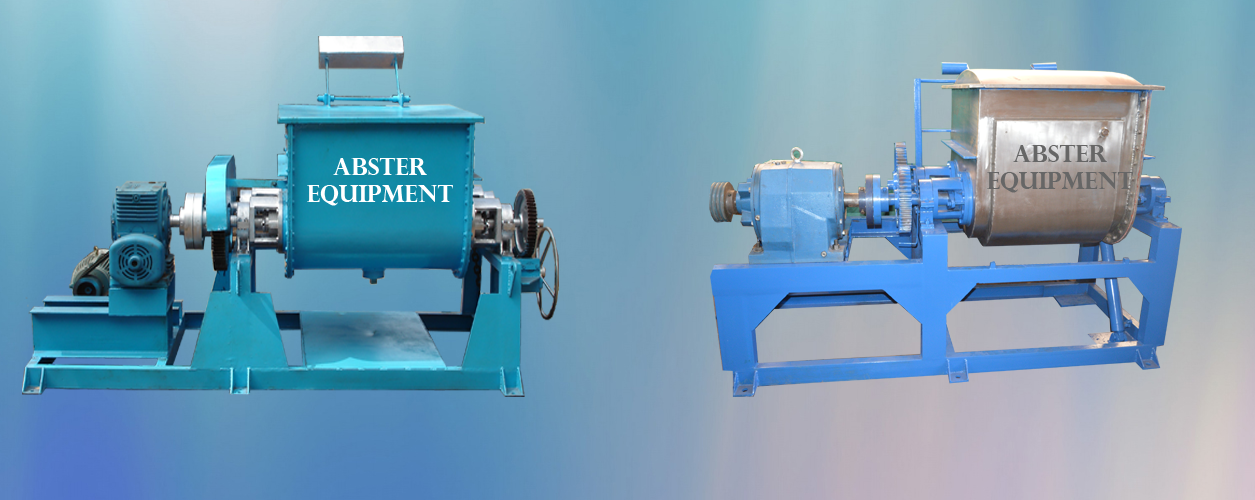

Sigma Blade Mixer

Double Sigma Mixer consists of two "U" shape container made of either Mild Steel or Stainless Steel(SUS304, SUS321, SUS316L),

Applications of the Sigma Mixer

The sigma mixer is the best suited mixer for pasty, sticky, and gritty slurries with high viscosities. The following are some

Operation of Sigma Blade Mixer

In operation, material is loaded through the top of the container to typically 40 to 65 percent of the mixer's total volumetr

Products

Sigma Mixer: ABF introduces the most sturdy, heavy duty SIGMA MIXER for trouble free long term operation for various application like mixing, kneading, grinding, dispersion, drying etc.

Our SIGMA MIXERS have application to process Viscous to highly Viscous material in various industries viz. Adhesives, Broke lining, Chemical, Confectionery, Carbon Black, Ceramic, Dyes & Pigments, Food Products, Fibre Glass, Grease, Lead Storage Battery, Magnetic Tape Coatings, Paint, Polymers Plastic, Putties, Plastic, Pharmaceuticals, Printing ink, Resin, Rubber, Soap & Detergent, Compounded Hing, Asafoetida Sigma Mixer etc.

Construction of Sigma Mixer:

SIGMA MIXER consist of “W” shaped container made of either Mild Steel or Stainless Steel 304 or 316 with jacket of Carbon Steel covering two side for heating or cooling application & dust free cover to get Vacuum if desired or normal cover.

The mixing elements (Blades) are of Sigma type Steel casted and duly finished two in number which contra rotate inward fitted at close or specified clearance with the container to give thorough and uniform mixing. There is a Gland pusher of Gun Metal Bush which ensure minimal friction and extend the life of mixing elements (Blades) Shaft.

Sigma mixer Drive

The Sigma Mixer Drive Consists of Motor of type TEFC or TEFC Flameproof of Specified HP. 1440 RPM, Reduction Gear Box Of Reputed Make having suitable size and ratio, Spur Gears, are also provided of adequate size and having machine cut teeth, between the front and rear blade complete with guard suitable for grease lubrication.

Features of Sigma Mixer

SIGMA MIXER as the name suggests contains mixing element (Blades) of Sigma type two in number which contra rotates inward to achieve end to end circulation & thorough & uniform mixing at close or specified clearance with the container. The mixed product can be easily discharged by tilting the container by hand lever manually either by system of gears manually operated or motorized.

Sigma Mixer, Sigma Mixers, Kneaders, Blenders, Heavier viscosity mixers, Dough Mixer, Stiff pastes and Adhesives mixer, Soap Mixer, Rubber compounds mixer, Sigma Mixer wholesalers India