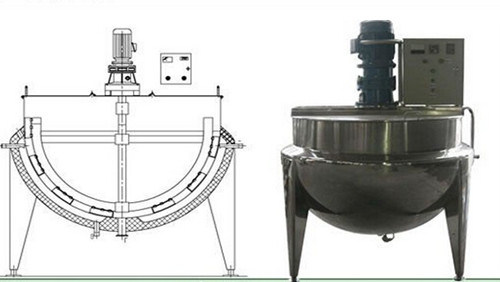

Starch Paste Kettle Steam Jacketed Starch Kettle

Sanitary stainless steel Starch Paste kettle(steam/electrical heating)

Material: SS304/316

Electric Heating Jacketed kettles

Stainless steel double-layered boiler/kettle ,used for heating, pasteurizing, cooking, mixing juice, sauce, fruit jam and processing meat, food, Candy, pharmacy, dairy , liquor, cake, drink, candied fruit, etc

Material: SS304/SS316

Heating by Electricity

* Type: with Jacketed wall

* Internal shell thickness: 3 or 4 mm, SS304

* Jacket thickness: 3 or 4mm, SS304

Starch paste kettle Specification:

| Product Name: | Stainless steel jacket kettle |

| Description: | Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosmetics and pharmaceutical industries |

| Construction: | vertical jacketed kettle,tilting jacketed kettle |

| Heating mothed | By electricity (oils or water), by steam, by gas |

| Material: | SS304/SS316L/1.4301/1.4404 |

| Capacity: | 50L-1000L |

| Agitator Type: | With PTFE scraper |

| Mechanical seal: | SIC/SiC/EPDM(Standard) |

| Motor power: | 0.55kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 7.5KW |

| Sealing option: | Sanitary single mechanical seal/Double mechanical seal with cooling system |

| Voltage: | 220V, 380V,415V |

| Motor: | ABB, LOCAL,50hz/ 60hz |

| Surface treatment: | Inner polished and outside polished |

| Availably connection: | Clamp, Thread Butt weld, Flange |

| Availably standard: | DIN, SMS, 3A, RJT, ISO/IDF |

| Operated: | Electic |

| Application scope: | Dairy, food, beverage, pharmacy, cosmetic, etc |

| Packaging Details: | Plywood case or customized. Or as per the request of customers |

| Delivery details: | Usually within 20 days after receiving T/T down payment |

Stainless steel double-layered kettle ,used for heating, mixing fruit jam and processing meat, food, Candy, pharmacy, dairy , liquor, cake, drink, candied fruit, etc

JACKET Kettle PART

Capacity: 300L TO 1000L

Material: SS304

Heating by Electric (380V, 440V50HZ)

* Type: with Jacketed wall

* Internal shell thickness: 3 mm

* Jacket thickness: 3 mm

stainless steel electric/steam/gas heating jacket kettle

| ABF100 | ABF150 | ABF200 | ABF300 | ABF400 | ABF500 | |||

| Capacity L | 100 | 150 | 200 | 300 | 400 | 500 | ||

| Jacketed pressure Mpa |

< 0.2 | |||||||

| Evaporation capacity kg/h |

40 | 50 | 65 | 75 | 100 | 150 | ||

| Heat area m 2 |

0.45 | 0.76 | 1.0 | 1.15 | 1.44 | 1.90 | ||

| Energy consumption kg/h |

44 | 55 | 72 | 90 | 110 | 165 | ||

| N.W. kg |

190 | 210 | 230 | 320 | 360 | 485 | ||

| LxWxH mm |

800X650X830 | 1350X650X1100 | 1400X700X1100 | 1450X800X1110 | 1500X850X1140 | 1600X900X1150 | ||

Steam Jacketed Kettle Starch Paste Kettle Jacketed Kettle, Steam Jacketed Kettle Starch Paste Kettle Jackete Kettle,

Steam Jacketed Kettle Starch Paste Kettle Jacketed Kettle

Binder Preparation Vessel

Functions

Basically This Unit Is Used For Preparation Of Starch Paste. Hemispherical Shape Ensures That The Heating Of The Starch Paste Is Uniform And Gets More Surface Area. The Tilting Type Arrangement Ensures Ease In Unloading The Paste Into Any Container Or Vessel. The Starch Is Put In The Kettle And Water Is Added Till Desired Thickness Is Achieved. The Kettle Is Jacketed And Is Heated Till Till The Starch Melts And A Thick Paste Is Achieved. This Paste Can Be Agitated Either Manually Or With The Help Of A Anchor Type Agitator Which Will Constantly Stir The Paste So That There Will No Lumps Formation And Proper Mixing Is Achieved. Temperature Can Be Set To Desired Temp By Adjusting The Thermostat Provided And The Temperature Can Be Seen In The Dial Thermometer Provided.